In Dallas, where the weather can range from scorching summers to mild winters, ensuring proper concrete prep for your garage floor is essential for longevity and appearance. The concrete needs to have the right balance of smooth and rough in order for any epoxy coating to stick. Imagine trying to slap a sticker on a dusty wall or bits of gravel — neither is going to end well!

How Do I Measure the Roughness or Smoothness of a Surface?

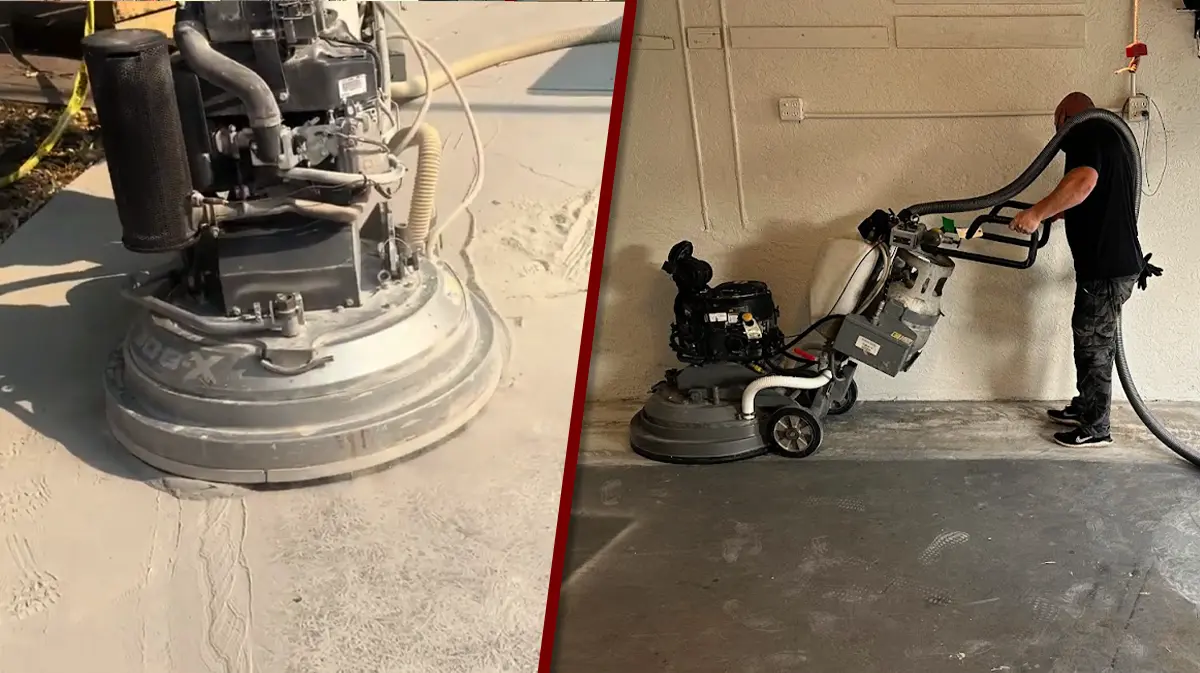

Concrete surface profile (CSP) is a measure of the roughness of the concrete surface, which needs to be just right for the epoxy coating to bond effectively. The International Concrete Repair Institute ranks CSP from 1 (very smooth concrete) to 10 (extremely rough). For epoxy coatings, a CSP of at least 3 is necessary. While methods like low-pressure water jetting, acid etching, and mechanical scarification often fall short by producing CSPs below 2, techniques such as grinding are ideal, achieving a CSP between 3 and 4. Propane grinders are particularly effective due to their power and efficiency. Despite a higher initial cost, they save time and reduce labor costs, making them a cost-effective choice in the long run.

Can I DIY It?

DIY epoxy coating projects often fail due to inadequate concrete preparation — it’s a fundamental skill in garage floors, but not one that is as intuitive as the floor installation itself. The equipment needed to achieve the right CSP is typically too expensive and specialized for most DIYers. Professional contractors have the necessary tools and expertise to ensure the concrete is properly prepared, resulting in a high-quality, durable epoxy coating.

Investing in professional services for concrete preparation and epoxy coating ensures your garage floor can withstand Dallas’s climate challenges. Properly prepared concrete provides a stable foundation for epoxy coatings, resulting in long-lasting and attractive finishes. Professionals understand the local conditions and apply their knowledge to deliver superior results.