In Dallas, epoxy flooring and polyaspartic coatings are popular choices for garages and commercial floors. Here’s a quick guide to help you understand the most common flooring terminology related to floor coatings.

Flooring Terminology: Epoxy Coating

An epoxy coating is just one of multiple coating types that can be used to create a coating system. Other coating types include polyurethanes, polyureas and polyaspartics. Epoxies are 2-component coatings, Part A, a resin, and Part B, a hardener. There are several epoxy sub-types: examples include DIY, moisture-tolerant, and moisture mitigating epoxies.

Quality epoxies are high-build coatings (i.e., they can be applied thickly), however they do have an Achilles heel. When exposed to UV light, epoxies can amber and fade. Because of this, these coatings are best used for interior installations (and exterior installations, including garages, if covered by a full flake broadcast or pigmented color coat).

Moisture-mitigating epoxies used in full-flake coating systems are unbeatable as direct-to-concrete primers. They cure slowly and deeply penetrate the concrete substrate creating a moisture vapor barrier. In Dallas, a moisture-mitigating epoxy is ideal as a primer coat for medium to high moisture concrete in commercial spaces, garages, basements, and other sub-spaces, providing long-lasting moisture protection.

Flooring Terminology: Polyaspartic Coating

Polyaspartics are low to no VOC 2-component coatings. They cure much faster than an epoxy (in under an hour) and provide extreme UV and chemical resistance. Like every coating type, however, polyaspartics have some disadvantages. They aren’t high-build coatings like epoxies (they can only be applied thinly) and cure very quickly. Curiously, they cure even quicker in the presence of moisture! As such, these coatings can be poor primer coats in medium to high concrete moisture conditions.

Because of this, polyaspartics are unbeatable as color or clear top coats, but not recommended as primer coats, especially in the presence of moisture. This makes them perfect for indoor and outdoor areas or garages…or any areas exposed to UV light and chemicals (including automotive fluids). Quality 100%-solids polyaspartics also provide resistance to hot-tire transfer, a process wherebu plasticizers in high-end tires leach into the concrete coatings. In Dallas, where the sun can be intense, a polyaspartic won’t yellow or degrade, giving you a long-lasting, beautiful floor.

Flooring Terminology: Polyurethane

This coating type uses an “older technology” that does not provide the binding strength or millage (“build”) of an epoxy. However, when applied in the proper re-coat window, say over an epoxy primer coat, it provides highly durable, application-friendly, UV- and stain-resistant flooring. However, beware of an additional limitation….polyurethanes are not recommended for garages as they are susceptible to staining by the plasticizers in “new technology” tires.

Given this limitation, polyurethanes are typically used on exterior patios and in buildings where vehicles are not parked for extended periods.

Garage Floor Coating

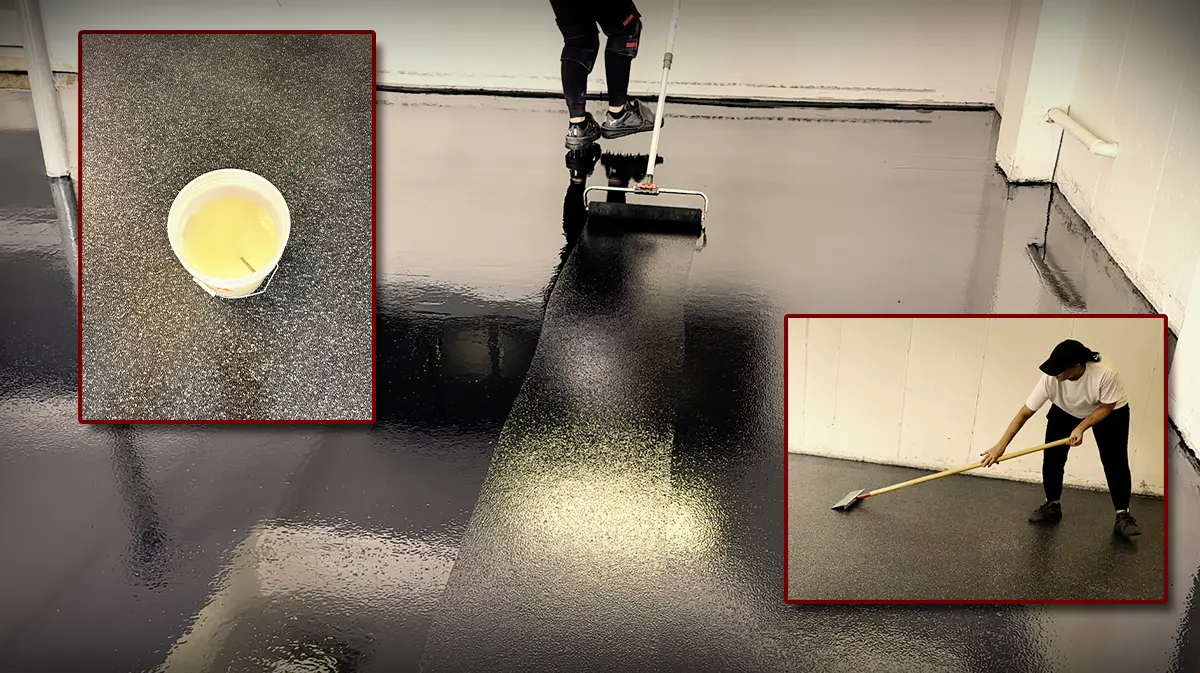

Garage floor coating typically refers to layered epoxy and/or polyurea-polyaspartic coatings that protect your garage floor from chemical spills, tire marks, and heavy loads. These coatings give your garage a professional, clean look that are easy to maintain, while providing the durability needed to withstand wear and tear.

Concrete Paint

While some people use the term concrete paint, it’s important to know that actual paint doesn’t offer the same protection as epoxy. In Dallas, where heat can cause traditional paint to peel or crack, epoxy or polyaspartic coatings are the better choice for long-lasting protection and durability.

Flake Epoxy Flooring System

A flake epoxy floor system is a decorative addition that also adds slip resistance to your floor. In Dallas, it’s popular in garages and basements, where safety and aesthetics are both important. You can choose from a variety of color flake blends to customize the look of your concrete floor coating while making it safer to walk on.

Epoxy Flooring: Moisture Mitigation

Dallas is known for high humidity. Hence, moisture mitigation is a key part of properly installing epoxy or polyaspartic coatings. By applying a moisture-mitigating epoxy as the primer coat (and saving the polyaspartic as the clear top coat), it prevents moisture-related issues like bubbling and peeling over time.

Conclusion

In Dallas, GarageFloorCoating.com offers top-notch epoxy and polyaspartic coatings to protect your floors from heat, heavy use, and daily wear. Understanding these terms will help you pick the right option for your space, ensuring long-lasting beauty and durability.